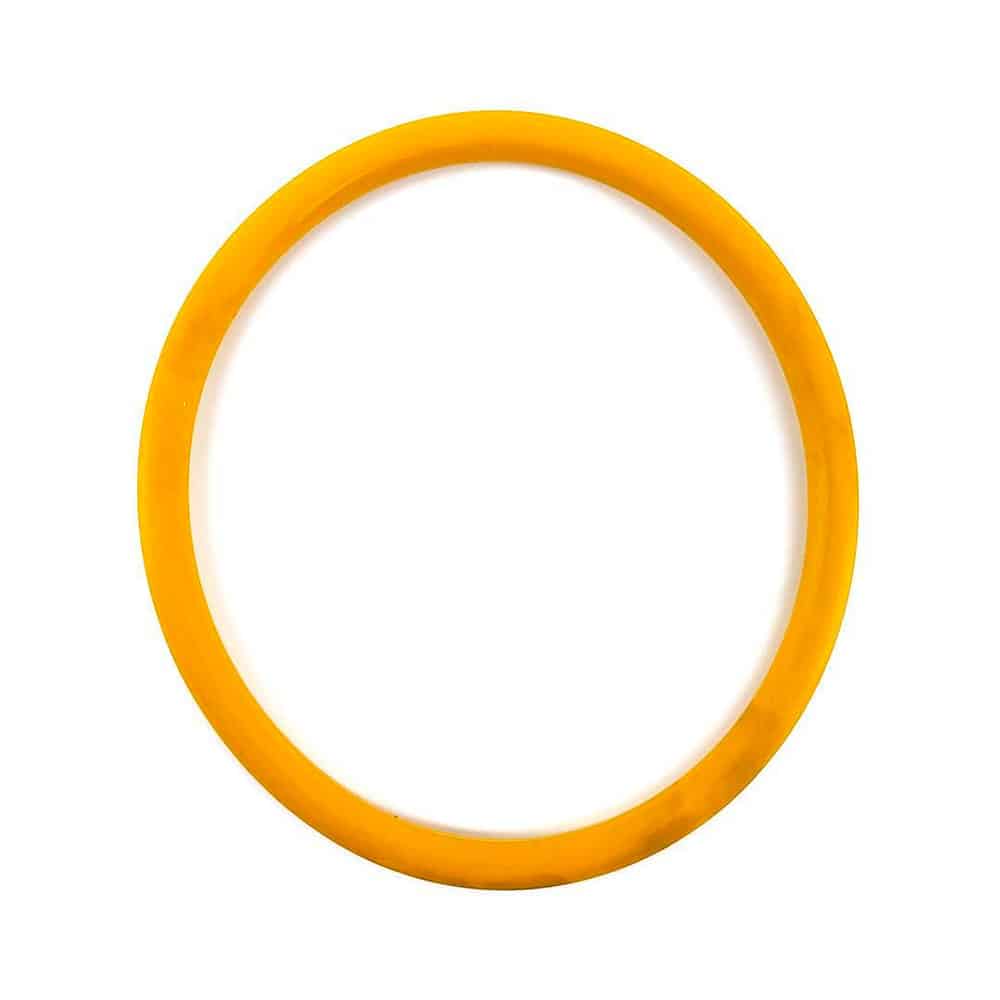

Pakning til lokk på Corneliusfat Low O2.

Pakning til lokk på Corneliusfat Low O2 er en pakning produsert i silikon. Dette er dessuten også den nye standarden til Corneliusfat.

Den unike konstruksjonen (Synthetic M-Class and Cross-Linked Elastomers) gjør dessuten også at denne pakningen har en bedre barriere mot oksygen enn de opprinnelige pakningene. Noe som også gjør at ølet ditt vil få bedre holdbarhet og den beskytter alt i alt bedre mot oksygen!

Vi bytter nå ut pakningene på alle våre fat etter hvert som vi bruker dem! Rart at ingen har kommet på dette før egentlig! Vi som brygger øl vet jo at ferdig brygget øl og oksygen er en dårlig kombinasjon. Ingen ønsker oksidert øl! Ta gjerne en titt på video nedenfor!

Du skal ikke alltid stole på det folk «sier», så her er en link til GunLab sin uavhengige test av produktet!

Du kan også lese testresultatene nedenfor!

16 January 2023

REPORT NO. 22153

TO: Kee Doery

KegLand Distribution Pty Ltd

410 Princes Highway,

Noble Park, Vic 3174.

OXYGEN TRANSMISSION TESTS OF O-RINGS

SAMPLES RECEIVED: 19/12/2022.

1. TEST RESULTS

OXYGEN TRANSMISSION RATE (OTR):

23 °C (±1°C), 0% or 90% RH inside, 50% RH (±5) out. Calculated to 100% oxygen at 1atm pressure.

cm³/day (Cubic centimetres of oxygen per 24 hours through one O-ring)

White O-rings

fitted to supplied keg-top

10.4 (@0% RH), 12.1 (@ 90% RH)

Mean 11.3 cm³/day

Yellow O-rings

fitted to supplied keg-top

0.43 (@0% RH), 0.39 (@ 90% RH)

Mean 0.41 cm³/day

2. NOTES:

2.1 We expect that most (or virtually all) of the measured transmission is occurring through the O-rings.

However, we have not attempted to measure the transmission (if any) occurring through the keg in/out

fittings, pressure valve etc. Any such transmission from fittings etc. would be included in the measurement.

2.2 Results are reported on a 100% oxygen basis, which is the convention for published OTR data.

Transmission in normal air (21% oxygen) would be 21% of the above results.

2.3 Oxygen transmission of both samples appears to be unaffected by changes in test humidity (RH).

3. TEST METHOD:

3.1 OTR: Based on ASTM F1307-02(2007), using Mocon Ox-Tran 2/22 and/or 2/21 instruments.

Test gas was a certified N2/O2 mix for the white O-ring, room air for the yellow O-ring. All results were calculated to 100%

oxygen at 1 atm. pressure.

Test time was about two days per test. Instrument calibration was done with Mocon standard reference films.

OTR test uncertainty: No information available for this variation of the method.

Bruce Gunn.

GunnLab® Photograph of keg-top connected to Ox-Tran 2/22 test instrument.

1. TEST RESULTS (Pakning til lokk på Corneliusfat Low O2)

OXYGEN TRANSMISSION RATE (OTR):

23 °C (±1°C), 0% or 90% RH inside, 50% RH (±5) out. Calculated to 100% oxygen at 1atm pressure.

cm³/day (Cubic centimetres of oxygen per 24 hours through one O-ring)

White O-rings

fitted to supplied keg-top

10.4 (@0% RH), 12.1 (@ 90% RH)

Mean 11.3 cm³/day

Yellow O-rings

fitted to supplied keg-top

0.43 (@0% RH), 0.39 (@ 90% RH)

Mean 0.41 cm³/day

. Om ønskelig!

. Om ønskelig!